Craft automatic cheesemaker for 60 liters - designed for making cheese at home, as well as in small industries, farms and restaurant bars. Cheese factory 6 0 liters , is fully automated and covers absolutely all processes in the preparation of any cheese. Automatic cheese dairy 60 l. Can be used on small farms!

The useful volume of the container for cheese making is 60 l . The total volume of the cheese factory (up the side) is 65 liters.

Volume of cheese produced per cooking: 60 liters of milk – from 7 kg. cheese

The cheese factory-pasteurizer allows you to perform absolutely all the processes necessary when preparing cheese:

- Automatic milk heating

- Automatic milk cooling

- Automatic pasteurization

- Maintaining the set temperature

- Ripening and increasing acidity of milk

- Curd maturation (fermentation)

- Slicing cheese curd horizontally and vertically using professional lyres

- Grain setting

- Automatic kneading of cheese grains

- Draining the whey and forming a cheese layer

- Partial draining of whey for deacidification or to form a cheese layer

- filling molds in bulk (using a drain tap)

All details of the Automatic Cheese Factory 60 l. made of food grade stainless, non-magnetic steel AISI 304, 1.5 mm thick. which makes it completely safe for use at home, as well as in the food industry. The shelf life of such containers, if used correctly, is practically unlimited. The cheese factory is processed by glass blasting, which reduces the tendency of the surface to become dirty, scratches and abrasions, thanks to which the appearance of the cheese factory will please you many times longer.

The cheese factory-pasteurizer is equipped with an electric heat-electric heater (TEH) at the client’s choice :

- 3-phase power 4.5 kW

- 1-phase power 3 kW

An automatic mixer will save you from the long procedures of kneading grain by hand and free up time for household chores while your cheese is being prepared. The control system allows you to set the speed of rotation of the mixer, as well as implement the “reverse” function, when turned on, the mixer begins to automatically change the direction of rotation after a time interval specified by you. The mixer has reversible blades, which automatically flip when changing direction, thereby creating a vertical rise of the cheese grain. Motor power 500 W.

Cheese factory 60 l. equipped with an automatic touch controller. This automation is incredibly easy to use and will allow you to easily and quickly manage and control all cheese making processes. Thanks to the electric valve that comes with the kit, the controller has the function of automatic pasteurization and cooling of milk.

The built-in timer will notify you with a sound signal about the end of time for a particular process of making cheese at home.

The new temperature sensor with a platinum element PT100 will allow you to maintain the temperature in the cheese bath with an accuracy of 0.1 C, while the controller controlled by the STM3000 microprocessor, which works according to the PID control protocol, will allow you to maintain the set temperature in the cheese factory, without inertia.

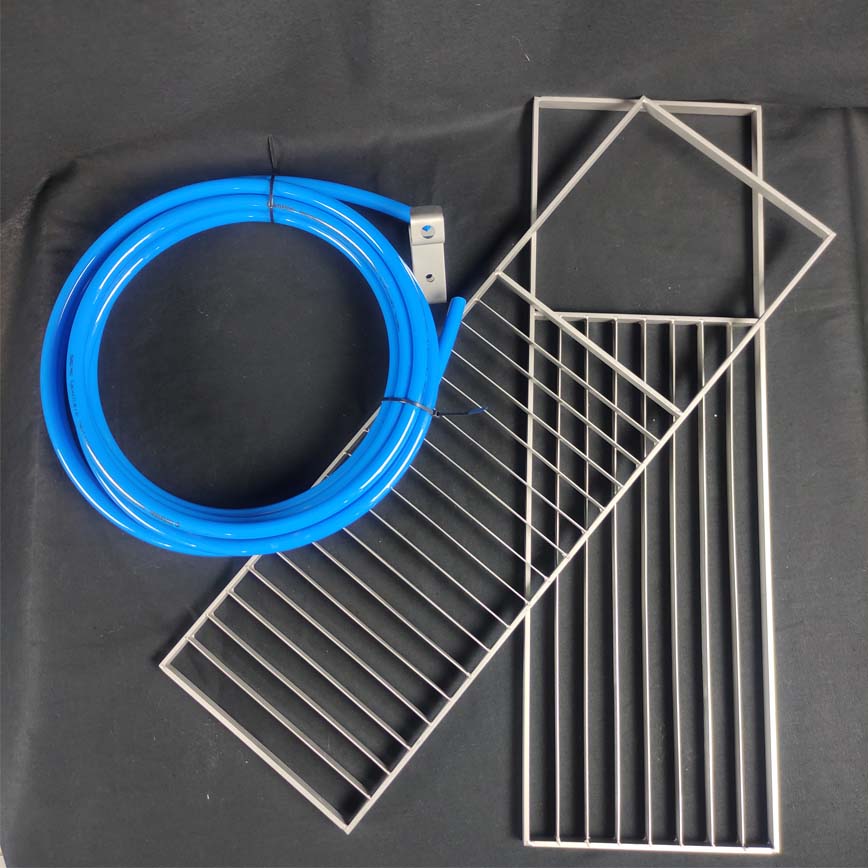

Included with the cheese factory you will receive two lyres (horizontal and vertical), made similar to industrial knives for cutting cheese curds, which will allow you to quickly cut the cheese curd and place the grain without resorting to additional improvised means.

The container of the pasteurizer cheese factory has a drain valve, with which you can drain part of the whey to carry out the grain deoxidation process, drain all the whey for further work with cheese grain, and also fill cheese molds using the pouring method.

Having a cheese book will allow you to retain the cheese grain without loss when draining the whey. You will achieve a result when all the grain remains in the cheese factory and you can safely continue to work with it. Carry out salting, filling molds, forming a layer and much more.

Please note that cheese factories are constantly being modernized, we do not always have time to change the information in the instructions and on the website, so your cheese factory may be slightly different from the one you see in the photo, and have new improvements and enhancements.

The basic package of the cheese factory includes:

- Capacity with a volume of 65 liters – 1 pc.

- Legs for cheese dairy – 4 pcs.

- Ball valve 1 inch – 1 pc.

- Drain 1 inch – 1 pc.

- Herringbone fitting 8 mm quick connect connection – 2 pcs.

- Stirrer – 1 pc.

- Cover consisting of 2 halves – 1 pc.

- Normally closed solenoid valve – 1 pc.

- Heating element (power depends on the selected type of connection) - 1 pc.

- Process control unit – 1 pc.

- Clamps and gaskets in the required quantity for assembly.

- Hose – 4 meters

- Lyre, for cutting the curd – 2 pcs.

- Knife-ruler for cutting curd - 1 pc.

- Curtain (book) for draining whey

- Trolley - 1 pc.

* You can also order an additional milk tap

To write a feedback